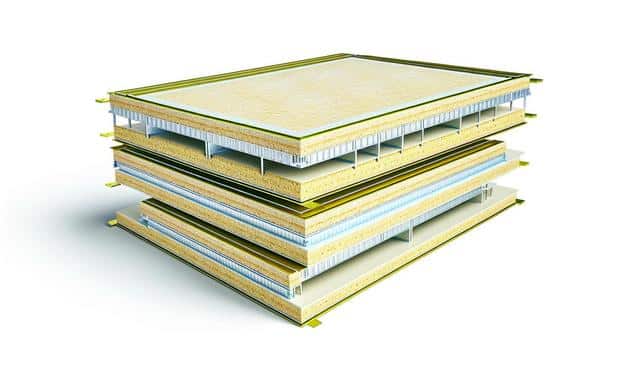

The Role of Sandwich Panel Sizes in Construction

The range of sizes available in sandwich panels plays a crucial role in accommodating diverse building requirements. Typically, these panels are manufactured in various thicknesses, widths, and lengths, allowing for customization as per the structural needs of a project. A larger panel can significantly reduce the time and labor costs involved in cladding a building due to fewer joints and faster installation processes. Additionally, different sizes can influence the structural integrity and load-bearing capabilities of a construction, making it vital to choose the appropriate dimensions to meet specific engineering demands. In essence, the versatility in sizes broadens the application scope of sandwich panels, making them suitable for everything from large industrial facilities to smaller residential homes.

Applications Across Industries

Sandwich panels find extensive applications across a myriad of industries, each benefiting from their unique attributes. In the industrial sector, they are frequently employed in constructing factories, warehouses, and cold storage units due to their insulation properties. Similarly, they play a pivotal role in the automotive industry, being utilized in vehicle bodies and shelters for their lightweight nature and structural strength. The aerospace sector also leverages sandwich panels for aircraft interiors, highlighting the material’s compatibility with weight-sensitive applications. This adaptability allows for innovative design solutions that cater to the specific performance requirements of different industries.

Environmental and Cost Benefits

Beyond their functional applications, sandwich panels offer notable environmental and economic benefits. Their inherent insulation capability can lead to reduced energy consumption, decreasing heating and cooling costs in buildings. Moreover, the materials used in sandwich panels are often recyclable, contributing to sustainable construction practices. Cost-wise, their prefabricated nature can shorten construction timelines, diminishing labor expenses and project durations. They also offer long-term savings in maintenance due to their corrosion resistance and minimal upkeep needs. As such, sandwich panels present a cost-effective solution in both short-term construction phases and over the lifecycle of a building.

Choosing the Right Sandwich Panel for Your Project

When selecting sandwich panels for a project, it’s essential to consider factors such as climate conditions, structural requirements, and intended use. Understanding the unique specifications and limitations of different panel types can significantly impact the efficiency and safety of the construction. Consulting with suppliers and construction professionals can provide insights into the most appropriate panel sizes and materials for your building needs. By taking an informed approach, you can ensure that the chosen sandwich panels not only meet your design and performance criteria but also serve as a reliable component of your construction endeavors.